This year’s Baja car is starting to take shape. Students with the Society of Automotive Engineers (SAE) have fabricated most of the front of the basic frame. The club is on track to finish the single-seat, all-terrain sport vehicle in time for the Baja SAE competition in Portland May 30-June 2.

Molly Fackelman gets some practice with one of the metal shaping machines in the MTC. “SAE has gotten me more experience in the machine shop than I would in my classes,” says the first-year mechanical engineering student.

Club members meet every Saturday in Gonzaga’s Manufacturing Technology Center (MTC) to continue building their design. On January 27, students continued bending, cutting, coping (shaping) and welding metal tubing for the frame.

“This is one of the few schools where you can get hands-on experience as early as freshman year,” said Project Manager Abraham Hobson, a junior mechanical engineering student. “Other schools have a waiting list to get on the team, make you watch the first or second year.”

Gonzaga’s SAE club specifically asked first- and second-year students to join the design team, and mechanical engineering freshman Molly Fackelman jumped at the chance. “It’s gotten me experience in the machine shop and with SolidWorks before I would have in classes,” she said. The car was designed with SolidWorks, a computer-aided engineering design program that students typically learn in their second year.

Although the club is specifically part of the School of Engineering and Applied Science, any student is invited to be part of SAE.

“Just because we’re engineers doesn’t mean we know everything,” said Jack Williams, a mechanical engineering sophomore. “The more people involved, the more ideas. Our lead driver is a business major, it’s staggering how much he knows about cars. He even advised us on what acrylic urethane to use.”

Last year’s Baja car is parked inside the east entrance to Herak, down the hall from the MTC. Each year the club makes some changes to the design but this year they decided to completely rebuild. The projected weight of the new car is at least 50 lbs. lighter than last year’s, which should improve the team’s results.

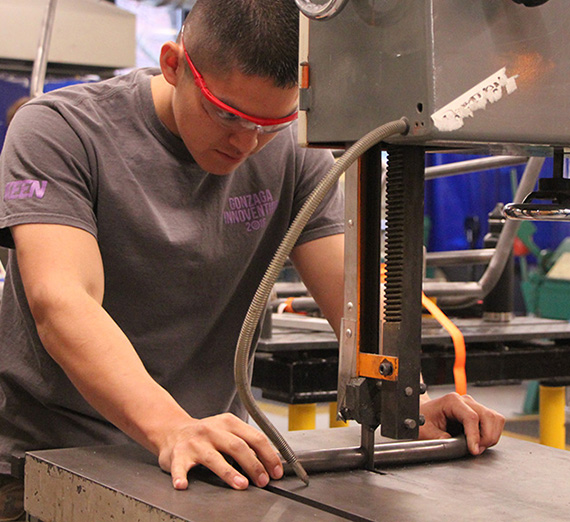

Abraham Hobson, a junior mechanical engineering student, fabricates the Baja Car front tow bar using a metalworking band saw in the Manufacturing Technology Center (MTC). Hobson helped lead the Frame Design team.

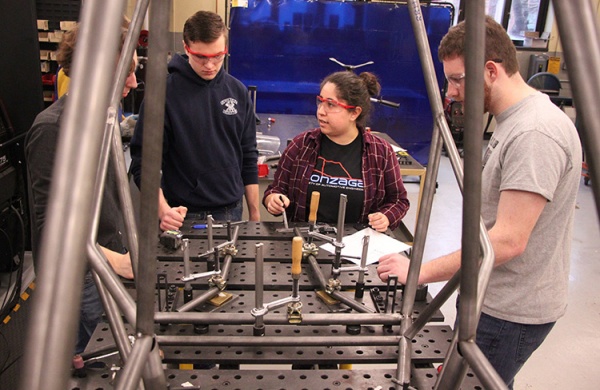

SAE President Isabella Verdugo (center) guides other club members on the designs for the back framework of the Baja Car. “The frame is made of extruded tubing to get uniform strength and symmetry all around,” she explains.

Jack Williams, mechanical engineering sophomore, welds the Baja Car’s tow bar to the frame.